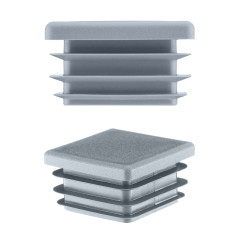

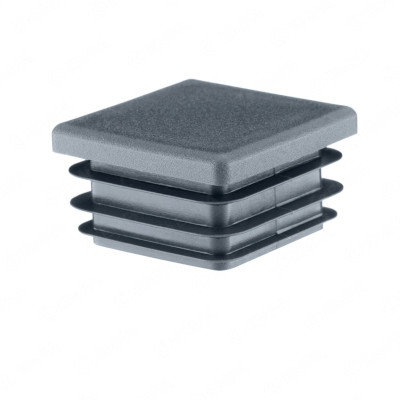

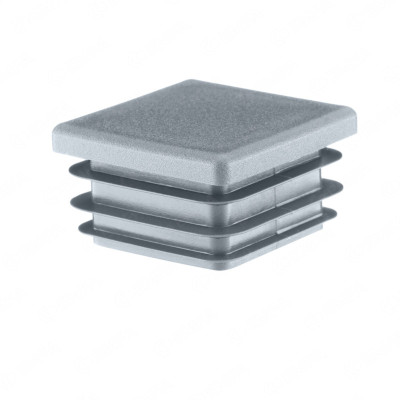

Square End Caps

Ribbed inserts for square tubing, also known as square tube plugs, plastic closure inserts for square profiles or internal profile end plugs, are essential components for securely sealing the open ends of square tubes. They combine functionality, protection, and aesthetics, making them ideal for constructions made from steel, aluminium, or plastics in industrial environments.

Anthracite

Choose a product...

White

Choose a product...

Black

Choose a product...

Grey

Choose a product...

Ribbed Inserts for Square Tubes – Precise Closure Solutions for Square Profiles

Material and properties

Our square tube inserts are manufactured from high-quality polyethylene (PE) – robust, long-lasting, and weather-resistant. The matte, scratch-resistant surface with slightly rounded edges integrates seamlessly into metal assemblies. Standard colour: black (RAL 9005); optional grey (RAL 7040), anthracite (RAL 7016), white (RAL 9010).

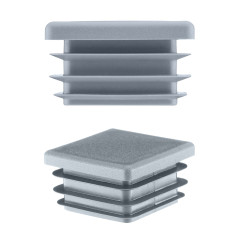

Ribbed fixation system

Four flexible ribs generate uniform pressure against the inner walls of the tube. This ensures a firm, vibration-resistant fit without adhesives or screws. During insertion, the ribs compress and then expand inside the profile.

Available sizes and wall thicknesses

Our range covers all common square tube dimensions for industrial applications:

- Small profiles: 10×10 mm to 30×30 mm — wall thickness 0.8–2.5 mm | applications: furniture, displays, lightweight structures

- Medium profiles: 40×40 mm to 60×60 mm — wall thickness 1.5–3.5 mm | applications: fencing, railings, metal construction

- Large profiles: 70×70 mm to 100×100 mm — wall thickness 2.0–5.0 mm | applications: load-bearing structures, machinery

- Special dimensions: 120×120 mm, 150×150 mm — wall thickness up to 12 mm | applications: heavy industrial constructions

Protective functions and safety

- Personal protection: Covers sharp edges and reduces the risk of injury (e.g. railings, playground equipment).

- Corrosion prevention: Blocks moisture from entering the inside of the profile.

- Contamination prevention: Stops dust, dirt, insects and – in industrial environments – chips and coolants.

Installation and handling

Installation is completely tool-free or supported by a light tap with a rubber mallet:

- Ensure the tube end is clean and free of burrs

- For thicker wall sections (>3 mm), lightly chamfer the edge (approx. 60°)

- Position the insert straight and press in evenly

- Check for a flush or slightly recessed fit

The inserts can be removed if necessary by gently prying them out with a flat screwdriver. This allows maintenance or part replacement.

Application areas

- Metal construction & steel structures: Beams, supports, frame profiles in halls, bridges, and industrial buildings

- Fencing industry: For square posts and crossbars; especially common sizes 40×40 to 60×60 mm

- Mechanical engineering: Machine frames, guide profiles, structural elements

- Furniture & shopfitting: Table and chair legs, shelving, retail displays

- Railing systems: Handrails and posts in stairwells, balconies, and public buildings

- Playground & sports equipment: Climbing frames, gym bars, safety-relevant structures

Differences compared with other closure solutions

- Ribbed inserts vs. external post caps: Internal insertion vs. external mounting

- Square vs. rectangular: Square inserts for equal-sided profiles, rectangular inserts for sizes such as 40×60 mm

- Plastic vs. metal: PE is corrosion-free, easy to install, and cost-efficient

Quality and warranty

- 10-year warranty on dimensional stability

- Precision manufacturing with tight tolerances

- Batch traceability for quality assurance

- Made in Europe

Delivery and packaging

- Delivery time: Standard sizes available from stock, shipped within 24 h

- Shipping: Free within Germany from €100 order value

- Business discounts: Automatically applied for registered business customers

- Custom offers for large projects & special dimensions (custom sizes, RAL colours)

FAQ – Frequently asked questions

1. What material are ribbed square inserts made from?

They are made of high-quality polyethylene (PE) – durable, weather-resistant, and impact-resistant. The matte surface is scratch-resistant and retains its shape for years.

2. Are they suitable for outdoor use?

Yes. They are designed for long-term outdoor applications and are resistant to rain, snow, sunlight, and temperature fluctuations. They are widely used in fencing and railing systems.

3. How do I find the correct size for my square tube?

Measure the tube’s outer dimension (e.g. 40×40 mm) and the wall thickness. Each product description specifies the compatible range. Free test samples are available on request.

4. How are ribbed inserts installed?

Simply press them in by hand or tap with a rubber mallet. The tube end must be clean and deburred. They sit flush or slightly recessed – adhesives are not required.

5. Are the inserts watertight?

They protect against splash water and rain but are not designed as pressure seals. For high-pressure environments, additional sealing measures are recommended.

6. Can the inserts be removed again?

Yes. Lift them gently with a flat screwdriver. If the ribs remain intact, the insert can be reused.

7. What is the difference between ribbed inserts and external post caps?

Ribbed inserts fit inside the tube for a flush finish; external caps fit over the tube and often have a domed top for water drainage.

8. Are other colours available?

Yes: black, grey, anthracite, and white. Custom RAL colours are available on request. All variants are UV- and weather-resistant.