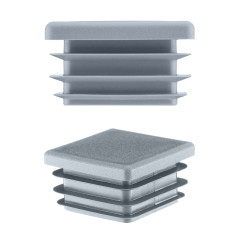

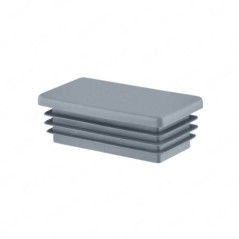

Insert End Caps

Ribbed plugs are technical components designed for sealing the ends of steel, aluminum, or plastic tubes. The flexible rib construction ensures a firm, vibration-proof fit without the need for adhesives – ideal for metal construction, fencing, mechanical engineering, and the furniture industry. Available in four shapes: square, rectangular, round, and oval.

Ribbed Tube Inserts – Closure Solutions for Tubes and Profiles

What are ribbed tube inserts?

Ribbed tube inserts (also referred to as internal tube plugs or tube closure inserts) are sealing elements designed for open tube ends. They are pushed into the inside of the tube and held in place by flexible ribs that generate consistent pressure against the inner tube walls. Unlike external caps or post-top covers, ribbed inserts sit flush or slightly recessed – without protruding edges.

Their function is based on elastic clamping: during insertion, the ribs compress and then expand inside the tube. This results in a firm, vibration-resistant fit without the need for adhesives, screws, or additional fixing elements.

Functionality of the ribbed mounting system

Ribbed tube inserts feature several flexible ribs arranged radially. These ribs are engineered to compress during insertion and then apply uniform pressure against the inner tube wall. This design provides several advantages: the insert adapts to different wall thicknesses (each size covers a tolerance range, e.g. 1.5–3.0 mm), it remains secure even under vibration and mechanical load, and installation is tool-free by simply pressing the insert into place.

Material and technical properties

Our ribbed tube inserts are manufactured from high-quality polyethylene (PE). PE is highly impact-resistant and remains flexible even at temperatures down to -40°C. The material is UV-stabilised and retains its mechanical properties for many years – even under continuous outdoor exposure. PE is resistant to moisture, saltwater, and most chemicals. Temperature range: -40°C to +80°C.

Available colours: We supply all common colours from stock – black (RAL 9005), grey (RAL 7040), anthracite (RAL 7016) and white (RAL 9010). All inserts have a matte, scratch-resistant surface with slightly rounded edges. The finish integrates seamlessly into metal structures and provides a professional appearance.

Available shapes and sizes

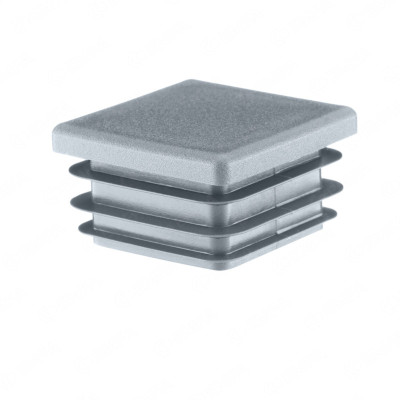

- Square tube inserts: For equal-sided profiles from 10×10 mm to 150×150 mm. Four ribbed sections provide uniform force distribution on all four sides. Suitable wall thickness range: 0.8 mm to 12 mm, depending on size.

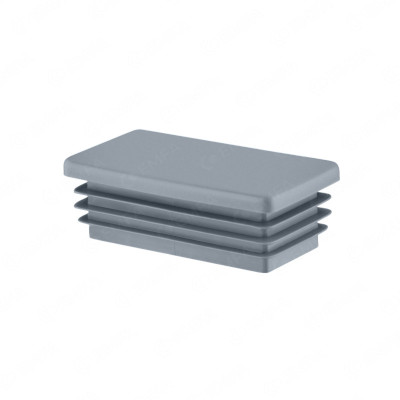

- Rectangular tube inserts: For profiles with different side lengths from 20×10 mm to 100×50 mm. Ideal for furniture, exhibition, and shopfitting applications. Suitable wall thickness range: 0.8 mm to 4.0 mm.

- Circular tube inserts: For round tubes from Ø 6 mm to Ø 120 mm. This is the most frequently used version; no rotational alignment is required during installation. Suitable wall thickness range: 0.5 mm to 5.0 mm.

- Oval tube inserts: For oval profiles from 20×10 mm to 80×40 mm. They combine ergonomic and aesthetic advantages of rectangular and round forms. Suitable wall thickness range: 0.8 mm to 3.5 mm.

Protective functions

- Personal protection: Open tube ends with sharp edges pose a significant risk of injury. This is particularly critical for railings, handrails, playground equipment, and furniture where people come into direct contact with the structure. Ribbed tube inserts cover these edges and minimise the risk of cuts and pinching injuries.

- Corrosion protection: Moisture entering tube interiors causes corrosion from the inside out. Ribbed inserts prevent water ingress and significantly extend the service life of steel structures – especially fences, railings, and outdoor constructions.

- Contamination protection: In production environments, metal chips, grinding dust, coolants, or welding residues can enter open profiles. Outdoors, insects, dirt, and leaves accumulate in tubes. Ribbed inserts keep these contaminants out and simplify maintenance.

- Aesthetic and professional finish: Closed tube ends create a clean, professional appearance – essential for visible constructions in furniture, shopfitting, and exhibition building. The flush finish without visible fasteners enhances the overall design quality.

Installation and handling

Installing ribbed tube inserts is tool-free and takes only a few seconds:

- Preparation: Ensure the tube end is clean and free of burrs. Remove sharp edges with a file or sandpaper to avoid damaging the ribs.

- Insertion: Position the insert straight and press it in evenly. For larger inserts, a rubber mallet may be used. Never use a metal hammer – this can damage the insert.

- Inspection: Check the fit. The insert should sit flush or slightly recessed and must not protrude beyond the tube end.

Reuse: Ribbed inserts can be removed if necessary. Carefully lift them with a flat screwdriver and pull them out. If the ribs remain intact, the insert can be reused – for maintenance, inspection, or component replacement.

Application areas by industry

- Metal construction and structural engineering: Used in beams, supports, and profile frames in halls, bridges, and industrial buildings. Particularly common: square 40×40 to 100×100 mm, circular Ø 40–80 mm.

- Fencing industry: Used in posts and crossbars made from square or round tubes. Inserts prevent water ingress and extend the durability of fence systems. Standard sizes: square 40×40, 60×60, 80×80 mm and circular Ø 42, Ø 48, Ø 60 mm.

- Mechanical engineering: Used in machine frames, guide profiles, and structural frames. Ribbed inserts protect against coolants, oils, and chips. Typical diameters: 30–60 mm.

- Furniture and shopfitting: Used in table and chair legs, shelving systems, display racks, and garment stands. Common sizes: rectangular 40×20, 50×25 mm and circular Ø 16–32 mm.

- Railing and handrail systems: Used in handrails and posts for staircases, balconies, and public buildings. Typical sizes: circular Ø 42, Ø 48 mm or oval 50×25 mm.

- Playground and sports equipment: Used in climbing frames, gym bars, football goals, and fitness equipment. They meet high requirements for impact strength, UV stability, and personal protection.

Differences compared with other closure solutions

- Ribbed inserts vs. external tube covers: Ribbed inserts are fitted inside the tube and sit flush. External tube covers (post caps) are mounted on top and often have a domed surface for improved water drainage.

- Ribbed inserts vs. threaded plugs: Threaded plugs are screwed in and offer higher load capacity, but they require pre-threaded tube ends. Ribbed inserts are universally applicable and faster to install.

- Plastic vs. metal inserts: Metal inserts offer higher mechanical strength. Plastic ribbed inserts are corrosion-free, lighter, more economical, and sufficiently robust for most applications.

Size selection and wall thickness compatibility

Choosing the correct ribbed tube insert requires two measurements:

- Tube outer dimension: e.g. 40×40 mm (square), Ø 48 mm (round), 40×20 mm (rectangular)

- Wall thickness: e.g. 2.0 mm, 2.5 mm, 3.0 mm

Each insert covers a range of wall thicknesses. Example: A 40×40 mm ribbed insert fits wall thicknesses from 1.5–3.0 mm. This tolerance simplifies selection and reduces the number of variants required.

Our product descriptions include detailed size tables with outer dimensions, inner fit dimensions, and wall thickness ranges. If you are unsure, we can provide free samples for testing.

Quality and warranty

- Precision manufacturing: High quality standards ensure an accurate fit.

- Quality control: Each batch is tested for dimensional accuracy and material performance.

- Long-term tests: Regular tests verify UV resistance, resistance to temperature cycling, and mechanical load capacity.

- 10-year warranty on dimensional stability and UV resistance.

- Made in Germany – reliability and consistent quality.

Delivery and service

- Delivery time: Standard sizes available from stock, shipping within 24 hours.

- Shipping costs: Free shipping within Germany from an order value of €100.

- Quantity discounts: Automatic tiered pricing for registered B2B customers.

- Free samples: Samples available on request for test fitting.

- Custom logo engraving: Individual branding with your company logo available from 500 pieces.

- Technical consultation: Our expert team supports you in product selection.

FAQ – Frequently asked questions about ribbed tube inserts

1. What material are ribbed tube inserts made of?

They are made of high-quality polyethylene (PE) – durable, weather-resistant, and impact-resistant. The matte surface is scratch-resistant and remains dimensionally stable for years.

2. Are ribbed tube inserts suitable for outdoor use?

Yes. All inserts are UV-stabilised and designed for long-term outdoor exposure, withstanding rain, snow, sunlight, and temperature fluctuations from -40°C to +80°C.

3. How do I find the right size?

Measure the tube’s outer dimension (e.g. 40×40 mm, Ø 48 mm) and its wall thickness. Each product lists the compatible tolerance range. If in doubt, free samples are available for testing.

4. How are ribbed inserts installed?

Simply press them into place by hand or tap gently with a rubber mallet. The tube end should be clean and free of burrs. No adhesives are required.

5. Are ribbed inserts watertight?

They provide reliable protection against splash water and rain, but they are not intended as high-pressure seals. For typical applications such as fences, railings, and furniture, the protection they offer is sufficient.

6. Can ribbed inserts be removed and reused?

Yes. Lift them gently with a flat screwdriver and pull them out. If the ribs remain intact, the inserts can be reused – for maintenance, inspection, or component replacement.

7. What is the difference between ribbed inserts and external tube covers?

Ribbed inserts are fitted inside the tube and provide a flush finish, while external tube covers are mounted on top and may include a raised profile for improved drainage. Ribbed inserts are more discreet; external covers provide enhanced weather protection for highly exposed posts.

8. Are different colours available?

Yes. Black (RAL 9005), grey (RAL 7040), anthracite (RAL 7016), and white (RAL 9010) are available from stock. All variants are UV-stable and colourfast.

9. Do you offer logo engraving?

Yes, from 500 pieces upwards we can engrave your company logo on the inserts. Contact us for a non-binding offer for customised branding.

10. Do ribbed inserts fit slightly oval tubes?

Yes, the flexible ribbed construction compensates for small deviations from the ideal round shape. For stronger ovalisation, we recommend requesting free samples and testing them in your application.